ADVANCED STEEL PROCESSING

For project ready steel, on site when you need it

For project ready steel, on site when you need it

At Southern Steel our advanced steel processing services offer a fast, comprehensive and cost effective solution to meet every customers requirements.

We consistently deliver value-added steel solutions to all market segments, including fabrication, construction, agriculture, transport and mining.

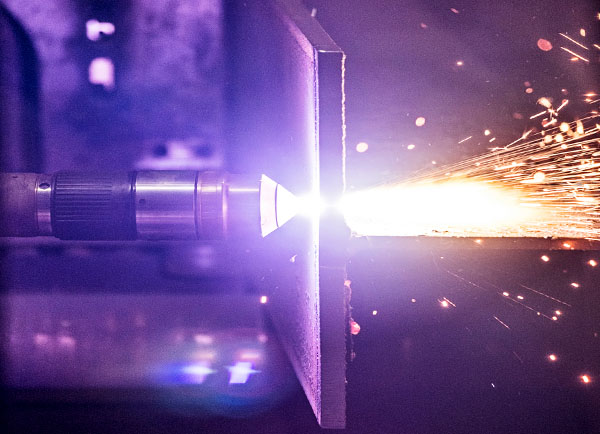

Our steel cutting services include custom metal cutting, coping and notching. We deliver plasma and oxy, profiling to 1mm tolerance. Coping, notching and mitre for beams up to 20m.

Drilling services include tapping, countersinking and drilling into steel plate. Drilling can also be done in the majority of structural steel available.

Advanced machinery ensures tight tolerances on all processed material, with capability up to 150mm plate. We also complete off-centre and on-centre drilling, deep hole drilling and gun drilling on processed plate.

Southern Steel is the expert supplier of profiled steel plates with the materials, skills and equipment to deliver your project needs – drill, countersunk and bevelled.

We work closely with you from tender to contract completion with the agility to meet short lead times.

Our advanced beam line equipment is fast, efficient and accurate. Our beam line cutting and drilling services include plasma and saw cutting, coping, notching and mitre cutting.

Our vast inventory of structural steel profiles across six stores includes beams, columns, channels, flats, angles, rectangular and square tubes, rails, DuraGal® Profiles, billets and blooms.

We can provide full CNC plate profiling solutions for any project utilising oxy and plasma cutting techniques. Drawing from our extensive stock range, we are able to supply profiled plate in 250,350, boiler, Q&T, and overlay material.

Our plate profiling service is efficient and fast. In addition to cutting we are able to offer hole drilling, countersinking, weld prep bevelling, and external rolling, pressing and bending services.

Independent chemical/mechanical charpy and ultrasonic testing is also available.

Our equipment capability in our Sydney workshop includes:

Ficep 1203 & 603:

| Welded beams | Up to 1200 |

| Welded columns | Up to 500 |

| Universal beams | Up to 610 |

| Universal columns | Up to 310 |

| Channels | 75 to 380 |

| SHS | 65 to 406 x 406 |

| RHS | Up to 508 |

| Mitre cutting | Up to 45° |

Voortman Cope/Drill Beam Line:

CNC Plate Profiling:

Our proud steel experts are ready to find the solutions you need. Contact your local branch in Sydney, Dubbo, Tamworth, Wagga Wagga, Newcastle or Wollongong for a fast response.

For fast, flexible and reliable steel supply